Cobalt is an essential component in the production of the main types of lithium-ion (Li-ion) batteries, such as the rechargeable batteries used to power portable electronic devices and electric vehicles…

Continue readingUncorrelaTEd

Solid-liquid thermoelectric systems with uncorrelated properties. Thermoelectricity, which can be used to recover energy from waste heat, is a niche technology with considerable growth potential, but limited by its low efficiency…

Continue readingSeNSE

Lithium-ion battery with silicon anode, nickel-rich cathode and in-cell sensor for electric vehicles

Lithium-ion batteries are the energy source of the future. Autonomy and rapid recharging are essential features to promote the adoption of electric vehicles. The EU-funded SeNSE project aims to create next-generation lithium-ion batteries with a silicon-graphite composite anode and a nickel-rich NMC cathode capable of achieving a volumetric energy density of 750 Wh/l. This new generation of batteries will also feature a sensor-based charge management system directly integrated into the cells to enable faster charging, improved durability and recyclability, and lower production costs.

ALION

The ALION (High Specific Energy Aluminium-ion rechargable decentralised electricity generation sources) project focuses on the development of Al-ion battery technology for energy storage via decentralised electricity generation sources…

Continue readingALISE

High energy lithium sulphur cells and batteries

ALISE (Advance Lithium Sulphur Batteries for Hybrid Electric Vehicle) focuses on the development and transition to commercial production and on understanding the electrochemical processes involved in lithium-sulphur batteries.

2015 / 2019 – Reference: H2020-NMP-GV-2014 – project n°666157

It aims to develop an innovative battery technology capable of meeting the needs of the European automotive industry in line with the European materials roadmap. The project aims to design batteries capable of reaching 500Wh/Kg in stable LiS cells.

It includes activities dedicated to durability, testing and life-cycle analysis that will ensure the safety and adequate cyclability of the batteries developed at a cost that should remain competitive. Initial materials research will be intensified during the course of the project, so that pilot-scale quantities of materials will be introduced into the new cell architectures, contributing to the advancement of the state of the art.

The project’s approach will enable real breakthroughs to be made in terms of components, cell integration and associated architecture. New materials will be developed and optimised for the anode, cathode, electrolyte and separator. Complete panels of specific tools and associated modelling will be developed from the single cell to the battery pack. Activities will focus on the development of new materials and processes at TRL4 level.

The lithium-sulphur technology will be demonstrated up to battery level, with on-board validation. Validation of the prototype (17kWh) with its corresponding range (100km) will take place on track. ALISE is more than a linear bottom-up approach from materials to the cell. This project aims to lay the foundations of solid resources for obtaining stable unit cells, with an additional top-down approach from the final application to the optimisation of the unit cell.

Method and apparatus for making electrodes for an ionic liquid-based supercapacitor

Process and device for manufacturing electrodes for a supercapacitor based on ionic liquid

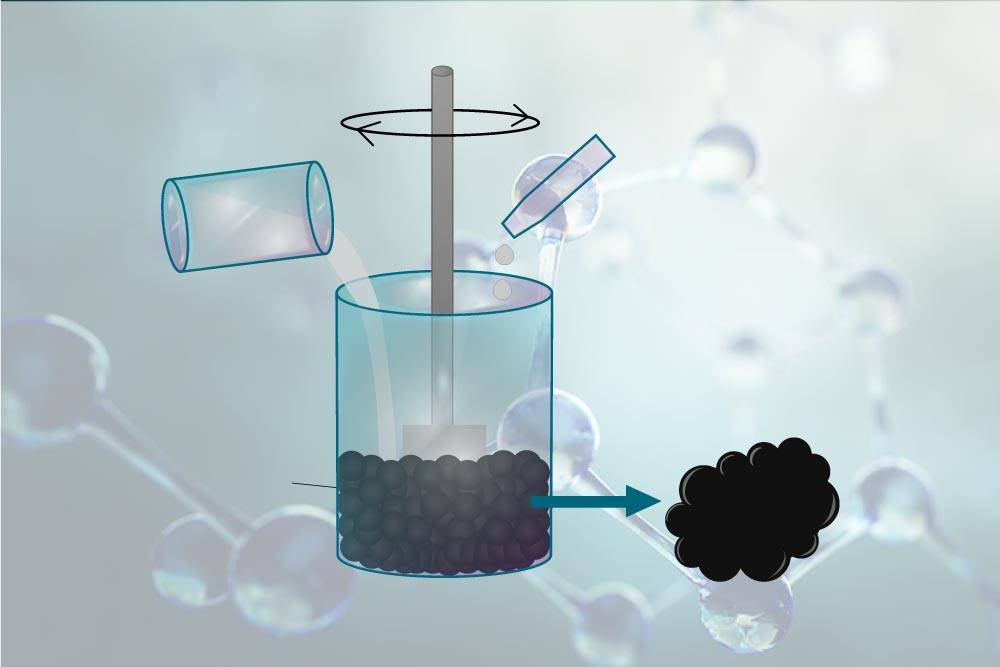

A method for making an electrode for an ionic liquid-based supercpacitor comprising two electrodes separated by an ionic polymer electrolyte separator.

Si-Drive

Silicon alloying anodes for high energy density batteries comprising lithium rich cathodes and safe ionic liquid-based electrolytes for enhanced high voltage performance.

Si-DRIVE is focusing on developing the next generation of Li-ion batteries based on an ionic liquid-based solid electrolyte, a silicon anode and a cobalt-free cathode.

Si-DRIVE will develop the next generation of rechargeable Li-ion batteries, enabling mass-market electric vehicles at a competitive cost thanks to processed materials and cell chemistry innovations, offering enhanced safety with superior energy density, life and fast charge capability, using sustainable and recyclable components. The technology encompasses amorphous silicon coated with a conductive copper silicide network as the anode with polymer/ionic liquid electrolytes and lithium-rich (cobalt-free) high-voltage cathodes via evolutionary processes, which can be manufactured in Europe. The components have been taken to TRL3 (Technology Readiness Level) through a preliminary lab-scale analysis, with a strategy of component improvement to achieve a prototype demonstration (TRL5) by the end of Si-DRIVE.

In-depth theoretical and experimental studies will probe and control the interfacial processes that have so far limited Li-ion technologies to marginal gains, looking at materials design and eliminating capacity-weakening mechanisms.

Si-DRIVE technology will exceed the stringent requirements of electric vehicle batteries, where safety is paramount, by dramatically improving each component of the Li-ion platform in a competitive, market-driven process over the entire life of the battery. The technology will also need to prove its suitability for reduced energy density second life applications beyond the main life of electric vehicles, prior to cost-effective recycling of materials in line with the circular economy.

The Si-DRIVE consortium has the expertise required from both academic and industrial partners to implement this technology. It will cover materials design and synthesis, electrochemical testing, prototyping and validation of production methods, life cycle assessment and development of recycling processes.

Publications

- Maresca, G.; Sankaran A.; Santa Maria LJ.; Ottaviani M.; Fantini S.; Ryan KM.; Brutti S.; Appetecchi GB. Superior compatibility of silicon nanowire anodes in ionic liquid electrolytes. Energy Mater. 2024, 4, 400017.

- M. Falco & al. An electrochemical compatibility investigation of RTIL-based electrolytes with Si-based anodes for advanced Li-ion batteries, Materials Today Sustainability, Volume 21, 2023, 100299, ISSN 2589-2347.

- O.Palumbo & al. So Similar, yet so Different: The Case of the Ionic Liquids N-Trimethyl-N (2-methoxyethyl)ammonium Bis (trifluoromethanesulfonyl)imide and N,N-Diethyl-N-methyl-N(2-methoxyethyl)ammonium bis(trifluoromethanesulfonyl)imide – Frontiers in Physics, 10 – 2022

- S. Brutti & al. – Ionic liquid electrolytes for high-voltage, lithium-ion batteries – Journal of Power Sources – Elsevier, 15 December 2020

- A. Cimini & al. Decomposition temperatures and vapour pressures of selected ionic liquids for electrochemical applications. J Therm Anal Calorim 142, 1791–1797 (2020).

- O. Palumbo & al. – Synthesis, Physical Properties and Electrochemical Applications of Two Ionic Liquids Containing the Asymmetric (Fluoromethylsulfonyl)(Trifluoromethylsulfonyl)imide Anion. Appl. Sci. 2022, 12, 4524.

- M. Falco & al. – A bilayer polymer electrolyte encompassing pyrrolidinium-based RTIL for binder-free silicon few-layer graphene nanocomposite anodes for Li-ion battery – Electrochemistry Communications, Vol 118, 2020, 106807, ISSN 1388-2481

MAGENTA

MAGENTA offers a completely new technological approach to research into thermoelectric materials for waste heat recovery applications.

Continue readingHELIS

High energy lithium sulphur cells and batteries

“HELIS (High energy lithium sulphur cells and batteries) focuses on the development Lithium-Sulphur cells. They will be tested according to automotive specifications.”

Thanks to their high theoretical energy density and cost-effectiveness, lithium-sulfur batteries (LSBs) are viable candidates for commercialization among all post-Li-ion battery technologies. But despite our best efforts, there are still problems to be solved… Some technological aspects, such as the development of host matrices, the interactions of the host matrix with polysulfides and the interactions between sulfur and electrolyte, have been successfully developed as part of the Eurolis project. The open porosity of the cathode, the interactions between host matrices and polysulfides, and the appropriate solvation of polysulfides all proved important for the full utilization of sulfur.We have also shown that effective electrode separation enables stable cycling with excellent coulombic efficiency. The remaining questions are mainly related to the stability of the lithium anode during cycling, the engineering of the complete cell and issues concerning the implementation of LSB cells in commercial products (ageing, safety, recycling, batteries). The instability of lithium metal in most conventional electrolytes and the formation of dendrites due to the uneven distribution of lithium during deposition are at the root of several safety problems, directly attributable to dendrites and low coulombic efficiency due to a constant increase in internal resistance linked to electrolyte degradation. Stabilizing the lithium metal and the interface layer will therefore have a major impact.

Seventh Framework Program (FP7)

Interfaces of Fluid Electrodes: New Conceptual Explorations

The Influence project aims to improve the fundamental understanding and control of the interfaces of semi-solid flow batteries, i.e. batteries based on Li-ion and Na-ion active materials.

Advanced Materials for Batteries

MAT4BAT develops batteries for electric vehicles based on advanced materials and pilot line processes, offering three new cell concepts derived from a combination of innovative materials.

InnovaTive Enzymes and Poly(Ionic Liquids) Based Membranes as CO2 Capture Technology.

The INTERACT project seeks to design processes capable of capturing CO2 after combustion via new materials, using ionic liquids and/or enzymes integrated into gas separation technologies such as gas separation membranes, absorption in columns and absorption using membrane contactors.

Publications

- I.R. Mazzei & al. – Poly[3-ethyl-1-vinyl-imidazolium] diethyl phosphate/Pebax® 1657 Composite Membranes and Their Gas Separation Performance. Membranes 2020, 10, 224.

- B. Grabner & al. Room-temperature solid phase ionic liquid (RTSPIL) coated ω-transaminases: Development and application in organic solvents, Molecular Catalysis, Vol 452, 2018, 11-19, ISSN 2468-8231

Materials for Ageing Resistant Li-ion High Energy Storage for the Electric Vehicle

The MARS-EV project aims to overcome the aging phenomenon associated with Li-ion cells by focusing on the development of high-energy electrode materials via sustainable, large-scale synthesis and safe electrolyte systems with improved lifetimes.

Cobalt and Lanthanide Recovery from Batteries

The COLABATS project aims to develop new industrial processes to improve the recycling of used batteries. This will increase the recycling efficiency in terms of energy consumption and purity of recovered metals. This process is all the more important as it involves critical and strategic metals such as cobalt and lanthanides, or nickel and lithium.

Advanced European Lithium Sulphur Cells for Automotive Applications

The aim of the project is to develop an advanced, durable lithium-sulfur (Li-S) battery for automotive use.