Liquid-Processed Solid-State Li-metal Battery: Development of upscale materials, processes and architectures.

Continue readingUncorrelaTEd

Solid-liquid thermoelectric systems with uncorrelated properties. Thermoelectricity, which can be used to recover energy from waste heat, is a niche technology with considerable growth potential, but limited by its low efficiency…

Continue readingLiquid compositions based on ionic liquids for the protection of lithium metal parts

An ionic liquid-based composition for protecting lithium metal anodes in a lithium-based electrochemical energy storage systeme, comprising a polymerizable ionic liquid (or ionic liquid monomer), the cation or the anion of which carries at least one polymerizable function, a non-polymerizable ionic liquid, an ionic liquid of the “crosslinker” type, the citation or the anion of which carries at least two polymerizable functions, and a lithium salt.

The ionic liquid-based polymer composition coated as such on the lithium surface, even if it is swelling with liquid electrolyte, protects the lithium against a constant electrolyte consumption and formation of unstable solid-electrolyte interphase (SEI), which is continuously forming on a bare lithium surface. The growing of dendrites is retarded with such ionic liquid-based polumer composition protection.

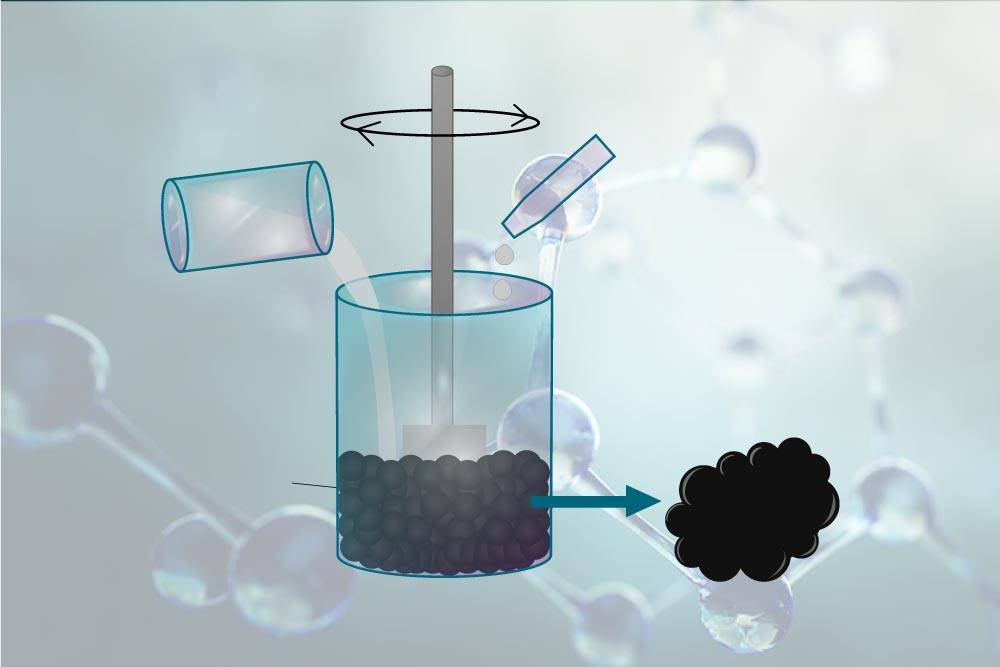

Method and apparatus for making electrodes for an ionic liquid-based supercapacitor

Process and device for manufacturing electrodes for a supercapacitor based on ionic liquid

A method for making an electrode for an ionic liquid-based supercpacitor comprising two electrodes separated by an ionic polymer electrolyte separator.

Si-Drive

Silicon alloying anodes for high energy density batteries comprising lithium rich cathodes and safe ionic liquid-based electrolytes for enhanced high voltage performance.

Si-DRIVE is focusing on developing the next generation of Li-ion batteries based on an ionic liquid-based solid electrolyte, a silicon anode and a cobalt-free cathode.

Si-DRIVE will develop the next generation of rechargeable Li-ion batteries, enabling mass-market electric vehicles at a competitive cost thanks to processed materials and cell chemistry innovations, offering enhanced safety with superior energy density, life and fast charge capability, using sustainable and recyclable components. The technology encompasses amorphous silicon coated with a conductive copper silicide network as the anode with polymer/ionic liquid electrolytes and lithium-rich (cobalt-free) high-voltage cathodes via evolutionary processes, which can be manufactured in Europe. The components have been taken to TRL3 (Technology Readiness Level) through a preliminary lab-scale analysis, with a strategy of component improvement to achieve a prototype demonstration (TRL5) by the end of Si-DRIVE.

In-depth theoretical and experimental studies will probe and control the interfacial processes that have so far limited Li-ion technologies to marginal gains, looking at materials design and eliminating capacity-weakening mechanisms.

Si-DRIVE technology will exceed the stringent requirements of electric vehicle batteries, where safety is paramount, by dramatically improving each component of the Li-ion platform in a competitive, market-driven process over the entire life of the battery. The technology will also need to prove its suitability for reduced energy density second life applications beyond the main life of electric vehicles, prior to cost-effective recycling of materials in line with the circular economy.

The Si-DRIVE consortium has the expertise required from both academic and industrial partners to implement this technology. It will cover materials design and synthesis, electrochemical testing, prototyping and validation of production methods, life cycle assessment and development of recycling processes.

Publications

- Maresca, G.; Sankaran A.; Santa Maria LJ.; Ottaviani M.; Fantini S.; Ryan KM.; Brutti S.; Appetecchi GB. Superior compatibility of silicon nanowire anodes in ionic liquid electrolytes. Energy Mater. 2024, 4, 400017.

- M. Falco & al. An electrochemical compatibility investigation of RTIL-based electrolytes with Si-based anodes for advanced Li-ion batteries, Materials Today Sustainability, Volume 21, 2023, 100299, ISSN 2589-2347.

- O.Palumbo & al. So Similar, yet so Different: The Case of the Ionic Liquids N-Trimethyl-N (2-methoxyethyl)ammonium Bis (trifluoromethanesulfonyl)imide and N,N-Diethyl-N-methyl-N(2-methoxyethyl)ammonium bis(trifluoromethanesulfonyl)imide – Frontiers in Physics, 10 – 2022

- S. Brutti & al. – Ionic liquid electrolytes for high-voltage, lithium-ion batteries – Journal of Power Sources – Elsevier, 15 December 2020

- A. Cimini & al. Decomposition temperatures and vapour pressures of selected ionic liquids for electrochemical applications. J Therm Anal Calorim 142, 1791–1797 (2020).

- O. Palumbo & al. – Synthesis, Physical Properties and Electrochemical Applications of Two Ionic Liquids Containing the Asymmetric (Fluoromethylsulfonyl)(Trifluoromethylsulfonyl)imide Anion. Appl. Sci. 2022, 12, 4524.

- M. Falco & al. – A bilayer polymer electrolyte encompassing pyrrolidinium-based RTIL for binder-free silicon few-layer graphene nanocomposite anodes for Li-ion battery – Electrochemistry Communications, Vol 118, 2020, 106807, ISSN 1388-2481

POLYSTORAGE

Training programme in new-generation polymers for energy storage

The POLYSTORAGE ETN project aims to design high-quality training courses in the field of “New-generation polymers used for electrochemical energy storage”.

The aim of this project is to train materials scientists capable of meeting Europe’s future energy and environmental challenges. The balanced combination of fundamental materials and polymer science with applied research in advanced energy storage devices is the keystone of this training network. A comprehensive training programme has been designed on two levels: local activities such as enrolment in PhD programmes, courses… and network-wide activities such as sectoral secondments, 6 workshops, 2 schools and a final conference.

The aim is to exploit the large number of potential synergies between innovative polymers and next-generation energy storage technologies, such as post-lithium batteries, redox flow batteries and all-polymer batteries. Industrial participants will be actively involved in training activities and in exploiting the results of the project. Solvionic is a partner organisation in the project.

Seventh Framework Program (FP7)

Interfaces of Fluid Electrodes: New Conceptual Explorations

The Influence project aims to improve the fundamental understanding and control of the interfaces of semi-solid flow batteries, i.e. batteries based on Li-ion and Na-ion active materials.

Advanced Materials for Batteries

MAT4BAT develops batteries for electric vehicles based on advanced materials and pilot line processes, offering three new cell concepts derived from a combination of innovative materials.

InnovaTive Enzymes and Poly(Ionic Liquids) Based Membranes as CO2 Capture Technology.

The INTERACT project seeks to design processes capable of capturing CO2 after combustion via new materials, using ionic liquids and/or enzymes integrated into gas separation technologies such as gas separation membranes, absorption in columns and absorption using membrane contactors.

Publications

- I.R. Mazzei & al. – Poly[3-ethyl-1-vinyl-imidazolium] diethyl phosphate/Pebax® 1657 Composite Membranes and Their Gas Separation Performance. Membranes 2020, 10, 224.

- B. Grabner & al. Room-temperature solid phase ionic liquid (RTSPIL) coated ω-transaminases: Development and application in organic solvents, Molecular Catalysis, Vol 452, 2018, 11-19, ISSN 2468-8231

Materials for Ageing Resistant Li-ion High Energy Storage for the Electric Vehicle

The MARS-EV project aims to overcome the aging phenomenon associated with Li-ion cells by focusing on the development of high-energy electrode materials via sustainable, large-scale synthesis and safe electrolyte systems with improved lifetimes.

Cobalt and Lanthanide Recovery from Batteries

The COLABATS project aims to develop new industrial processes to improve the recycling of used batteries. This will increase the recycling efficiency in terms of energy consumption and purity of recovered metals. This process is all the more important as it involves critical and strategic metals such as cobalt and lanthanides, or nickel and lithium.

Advanced European Lithium Sulphur Cells for Automotive Applications

The aim of the project is to develop an advanced, durable lithium-sulfur (Li-S) battery for automotive use.